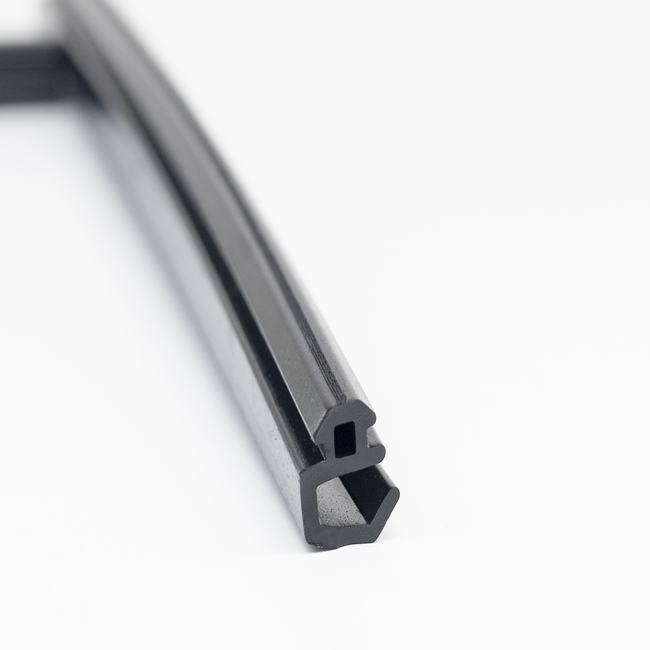

EPDM (Ethylene Propylene Diene Monomer) rubber gaskets are versatile sealing components widely used in various industries and applications due to their excellent properties and durability. EPDM rubber is known for its resistance to weathering, ozone, UV radiation, and a wide range of chemicals, making it suitable for both indoor and outdoor use. Here’s more information about EPDM rubber gaskets:

Key Features and Characteristics:

- Excellent Weather Resistance: EPDM rubber gaskets are highly resistant to environmental factors such as sunlight, rain, and temperature fluctuations. They do not degrade or become brittle when exposed to the elements, making them ideal for outdoor applications.

- Chemical Resistance: EPDM rubber has good resistance to a wide range of chemicals, including acids, alkalis, and polar solvents. This makes it suitable for various industrial environments.

- Temperature Resistance: EPDM gaskets can withstand a broad temperature range, from -40°C (-40°F) to 120°C (248°F) or even higher, depending on the specific formulation. This makes them suitable for both hot and cold applications.

- UV Stability: EPDM rubber is resistant to ultraviolet (UV) radiation, which prevents it from deteriorating or breaking down when exposed to sunlight over extended periods.

- Elasticity and Flexibility: EPDM rubber is highly flexible and has excellent elastic properties, allowing it to maintain a secure seal even in applications with movement or vibration.

- Low Water Absorption: EPDM has low water absorption properties, which help it maintain its sealing effectiveness even when exposed to moisture.

Applications of EPDM Rubber Gaskets:

EPDM rubber gaskets find a wide range of applications across various industries, including:

- Automotive: EPDM gaskets are used in automotive engines, doors, windows, and weatherstripping due to their resistance to engine fluids, weather conditions, and temperature variations.

- Construction: They are used in building and construction applications for sealing windows, doors, roofing, and HVAC systems.

- Electrical and Electronics: EPDM gaskets can provide electrical insulation and environmental sealing in electrical enclosures, control panels, and outdoor electrical installations.

- Industrial Equipment: EPDM gaskets are used in pumps, valves, and pipelines to create leak-proof seals in chemical and industrial processing.

- Marine: EPDM gaskets are suitable for marine applications, including sealing hatches, ports, and other openings on boats and ships.

- Agriculture: EPDM gaskets are used in irrigation systems, agricultural equipment, and machinery due to their resistance to moisture and chemicals.

- Medical Devices: EPDM rubber’s biocompatibility makes it suitable for use in medical devices and equipment, where a reliable seal is essential.

Maintenance and Care:

To ensure the continued effectiveness of EPDM rubber gaskets, regular inspection for wear, damage, or deterioration is essential. Gaskets that show signs of cracking, tearing, or loss of elasticity should be replaced promptly. Proper storage away from direct sunlight and exposure to harsh chemicals can also help prolong their lifespan.

In summary, EPDM rubber gaskets are highly versatile sealing components known for their excellent weather resistance, chemical resistance, and temperature stability. They play a crucial role in creating reliable and durable seals in various industrial and commercial applications, contributing to the efficiency and longevity of systems and equipment.